The billion-dollar opportunity for ‘data smart’ manufacturers

By Dr Dzaharudin Mansor February 25, 2015

- At the centre of manufacturers’ quest for reimagining their organisations is data

- Once a manufacturer connects discrete data sources, data evolves into insight

THE technology marketplace today is full of buzz about big data and the Internet of Things. Today’s more pervasive and intelligent sensors and devices, connected to globally integrated and connected enterprise systems, analytics services and the cloud, are transforming industries, right now.

THE technology marketplace today is full of buzz about big data and the Internet of Things. Today’s more pervasive and intelligent sensors and devices, connected to globally integrated and connected enterprise systems, analytics services and the cloud, are transforming industries, right now.

The manufacturing industry is no exception.

Asia’s manufacturing industry has enjoyed phenomenal growth in the last two decades, giving rise to the term ‘Factory Asia.’

However, J.P. Morgan’s latest global manufacturing PMI report showed a drop in production in the region, as seen through the declines in China, South Korea and Indonesia, and notably, in Japan following a recent increase in sales tax.

Against this backdrop of variability in the manufacturing sector, one thing is certain: Manufacturers in Asia must look beyond just new ways to automate and create efficiency, and focus on new opportunities for innovation in their operations and business models.

At the centre of their quest for reimagining their organisations is data.

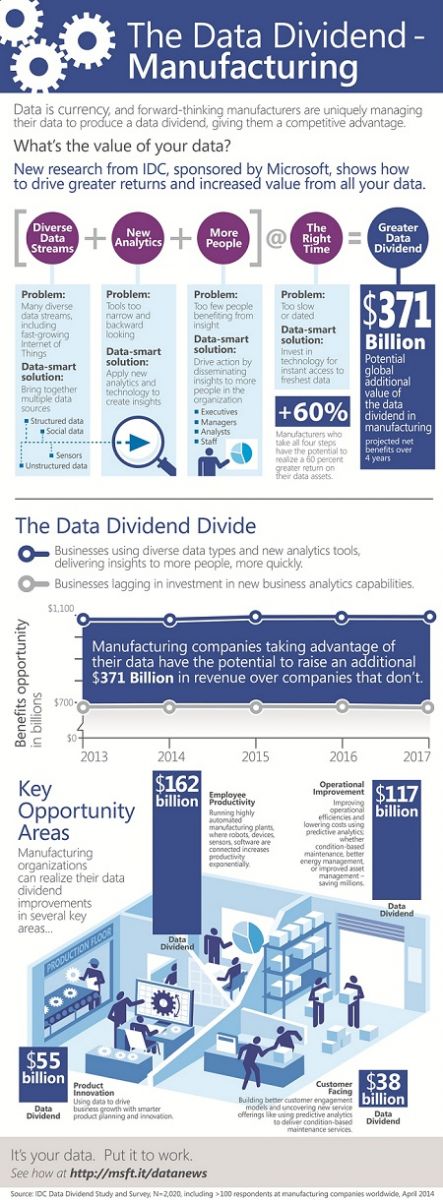

According to recent research by IDC, commissioned by Microsoft, manufacturers stand to gain a whopping US$371 billion in value from data over the next four years.

According to recent research by IDC, commissioned by Microsoft, manufacturers stand to gain a whopping US$371 billion in value from data over the next four years.

Manufacturing companies which leverage their data have the ability to gain greater visibility and insights to derive breakthrough productivity and reimagine enterprise processes, but also understand and manage customer experiences in real-time and increase the rate of differentiated innovation and service offerings.

The IDC study looked at companies globally to better understand what actions by ‘data smart’ manufacturing organisations yield the most impactful outcomes, both in terms of growth and efficiency.

The US$37 billion is the potential net value – what we refer to as the ‘data dividend’ – for the manufacturing sector if companies become data smart and perform some combination of the following four actions:

- Bring together even as few as three to four discrete data sources.

- Use modern analytics tools to glean insights from data.

- Surface those insights in a consumable fashion to the right decision makers across the company.

- Ensure that insights from data are shared in a timely manner.

Manufacturing organisations that take all four of these steps potentially stand to realise a 60% greater return on their data assets.

While the incentive to be ‘data smart’ is compelling, it’s easy to develop a case of analysis paralysis when it comes to big data: Where to start? What data to collect? Who really needs it? How do we deliver insights in a consumable way to the non-data scientists – the business decision makers in your manufacturing organisation?

For one manufacturing plant, the pressing business issue might be predictive maintenance of its expensive capital assets, for another it might be building smarter supply chains, and for yet another, the driving need to use data might stem from improving efficiencies in its automated production lines.

Whatever your business imperative, the right data – big, small, or any other kind – surfaced at the right time, and with the right decision maker to drive impactful action, is a manufacturer’s ticket to a piece of the US$371-billion data dividend opportunity.

What’s next? Competing in the IoT age

Everyone wants a leaner, more efficient factory floor, but in many ways, production efficiency tapping insights from data is just the low-hanging fruit.

With the rise of these connected and intelligent operations, manufacturing executives are also focusing on a big new opportunity for revenue growth: Services.

Services represent new and recurring sources of revenue that can be more appealing than just selling the device or the equipment – think of selling a monthly subscription for new razors or toothbrushes, as opposed to a single item.

This trend is already leading to a big change in how manufacturers re-imagine themselves and their relationship with customers.

The evolution of the car is a telling example. Technology in the car has become a top driver of purchasing decisions, leading auto manufacturers to rethink their customer relationship.

In the past, that relationship largely ended at the point of invoicing the sale, but today, an auto manufacturer is also a technology provider. Managing the customer’s experience post-sale and engaging the customer throughout the vehicle ownership lifecycle with rich, ongoing online services has become the core strategy for leading automotive manufacturers.

This is where the right data captured at the right time and delivered to the right employee within an organisation – what is often referred to as the democratisation of data – will be a game changer.

Once the manufacturer connects discrete data sources across devices, processes, people and external networks, data evolves into insight.

Replacement parts and updates can be sent proactively, repairs scheduled, inventory needs and expenses anticipated much more accurately. All of these are workflows that have traditionally taken a lot of effort, energy and disruption on the part of customers and resulted in bad customer experiences.

Of all the decisions that manufacturers need to make as they embark on this journey, looking at the wingspan of their technology partners may be the most important.

Trust, familiarity of software applications for workers, domain expertise, intelligent and secure cloud services for connecting machine-generated data, a scalable big data cloud platform that spans devices and services, interoperability, a rich partner ecosystem – these are but a few of the criteria manufacturers are using to evaluate their technology choices as they move toward that fourth industrial revolution.

The potential rewards for organisations that embrace a data culture in the world of ubiquitous computing are clear. And despite the unknowns, the lure of that potential is already creating a new wave of innovation for the industry.

The only question for manufacturers now is, will they ride that wave, or will it knock them off their feet?

Dr Dzaharudin Mansor is the national technology officer at Microsoft Malaysia.

Related Stories:

US$278bil worth of data dividend potential in APAC: IDC, Microsoft

Connecting the healthcare dots with big data

Make your data work for you

For more technology news and the latest updates, follow us on Twitter, LinkedIn or Like us on Facebook.